ULTRAVIOLET WATER TREATMENT SYSTEM

Ultraviolet Water Treatment System or Ultraviolet Purification System is a proven way to safeguard drinking water. Once a Perfect UV water purification system is installed then the issues related to taste,odor will be resolved. UV water purification is effective and environmentally safe.

Ultra violet water treatment systems (UV sterilisers) kill bacteria in water. They are often used to ensure safe drinking water from well, spring and borehole water supplies. Due to increased legislation are now regularly used in food and drink related industries.

Micro organisms including bacteria, viruses and cysts are all around us naturally. Many are harmless but exposure to “bad” ones can cause severe illness particularly in the elderly and very young. There is a wide variety of water treatment products available to improve taste, clarity, scale etc but none of these are designed to combat bacteria. Ultra violet water treatment is one of the safest ways to disinfect water as the UV rays are a natural component of sunlight. No chemicals are added so there is no danger from overdosing or creating a bad taste

How does Ultraviolet disinfection system work?

The Micro organic contaminants are to exposed to lethal amount of Ultraviolet Light at a particular wavelength. The exposure makes the microorganism to be inactive. Pathogens which are considered to be a threat is removed completely using UV filtration system. Pathogens Ex: Cryptosporidium, Giardia, Salmonella, E.Coli

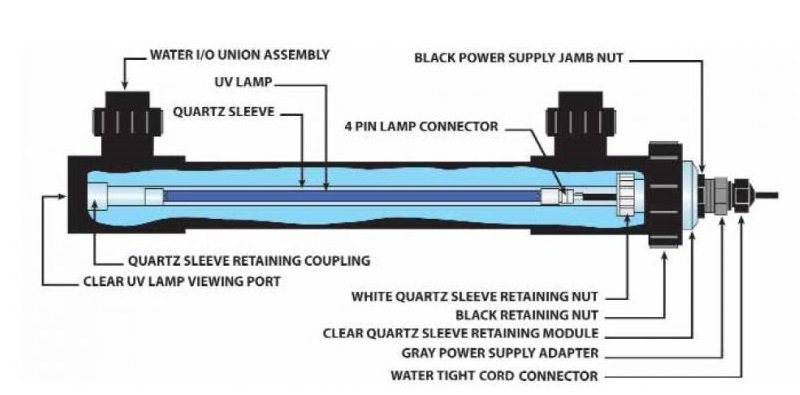

Using UV light in drinking water treatment requires the generation and application of UV light in a way to maximize its effectiveness. All UV drinking water treatment devices require power to generate UV light. When a UV lamp is turned on, mercury in the lamp is “excited” and takes on energy. The mercury quickly discharges that extra energy in the form of UV light. Mercury is a necessary component of UV lamps because it emits light in the germicidal wavelength (200-300 nm). However, there are new UV light emitting-diodes (UV LEDs) being developed that do not use mercury and show promise as effective UV disinfection devices. A UV device used in drinking water treatment typically consists of a UV lamp, a clear quartz sleeve to protect the lamp and allow the UV light to penetrate the water, and in some cases a means to measure the intensity of UV light produced. Having the ability to measure UV light intensity is important since certain water quality characteristics can reduce intensity and UV

intensity degrades the more the lamp is used.

Additionally, the UV device is designed to ensure all the water being treated is channeled through the device as close to the quartz sleeve as possible to ensure the water receives the longest amount of exposure possible at the maximum UV intensity. UV devices work best when treating clear water, so UV devices are typically located after filtration treatment processes. The effectiveness of UV light is highly dependent on the turbidity, or cloudiness, of the water and any color present in the water. In highly turbid or colored water the UV light won’t be able to penetrate through the water. A well-designed UV device will incorporate indicators of operation to measure the UV intensity, or UV dose, provided to the water and will also include indicators of lamp function (on/off). UV devices can be scaled to fit any size or type of drinking water treatment need, from small handheld devices to large systems capable of treating millions of gallons per day. A number of commercially available water treatment systems designed to fulfill the needs of the military squad sized unit incorporate UV as a disinfectant. These water purifiers are meant to be portable and therefore present inherent risk of breakage or damage to the UV device during transport. Care must be exercised when transporting a UV device and they should be closely inspected prior to operation to ensure no damage has occurred. A significant disadvantage of using UV for disinfection is its inability to provide a residual. If UV disinfected water is to be stored a chemical disinfectant such as chlorine or iodine, capable of providing a long-lasting disinfectant residual, should be added to the stored water to prevent re-contamination.

Factors affecting Ultraviolet Water Treatment Effectiveness

The following factors are common obstacles that will reduce the effectiveness of UV disinfection:

- Particulates and sediment. These suspended solids will block the UV Rays from passing through the water. They can act as a shield, “protecting” germs from UV light. Suspended solids should be physically removed from water by mechanical pre-filtration before the water goes to a UV system.

- Iron/manganese will cause discoloration on the quartz sleeve that surrounds the UV lamp and reduces the transmission of UV light, they will also absorb UV energy. Iron and Magnesium should be removed from water by pre-treatment or at least reduced to no more than .3 ppm for iron and no more than .05 ppm for manganese.

- When water is hard, scale will eventually build up on the quartz sleeve around the UV lamp and will stop the UV light from passing through. A water softener should be used before an UV unit if the water is hard.

- Other organic and inorganic dissolved substances can also reduce the germicidal effectiveness of UV light and should be pre-treated before an UV unit.

Advantages of Ultraviolet Water Purification

Excessive bacteria counts in water may require an additional UV dosages or chemical treatment. Other factors, such as water temperature, should also be considered. UV units are normally designed to operate best between two and forty degree Celsius. Apart from these UV treatment method has also other benefits such as,

1. Effective destruction of Microorganisms

2. No Harmful chemicals needed.

3. One Time Installation and Periodic service

4. Reliable system to treat water.

5. Keeps Environmental Safe and Clean

6. Less Energy Required

7. More Water Conservation

8. An Easy as well as effective than Chlorination

9. Quick and Cost Effective Process

10. UV treatment does not change Taste / Odor

UV Lamps for Industrial Water Treatment :

- Process water: Industry requires clean, disinfected water for many purposes – such as rinsing and cleaning processes and production processes in the food and beverage industry and in the cosmetics-, chemistry- and automobile industries, where water is recycled and re-used.

- Air cleaning: Water is disinfected in air conditioning systems and humidifiers. No biocides are released into the air.

- Aquaculture: Water can be treated to allow the controlled farming of fish, mussels, crabs and plants in flowing or still water. This protects the farming of external environmental influences and also saves water.

- Agriculture: Farming uses a lot of water in greenhouses and growing frames. Pathogens can easily be formed in the irrigation water in such enclosed water circuits. If this water is re-used, the pathogens can be spread throughout the irrigation system, with detrimental effect on plant growth and on the health of personnel.

- Disinfection ensures a good harvest.

- Ballast water: As international shipping traffic expands, site-directed organisms are regularly taken in by ballast water and then introduced into different ecosystems. These organisms can be destroyed by on-board.

- Injection water for oil extraction: Water is treated and re-used on oil production platforms.

- Activated oxidation (UV+H2O2; UV+O3): Various advanced oxidation processes can be combined with UV disinfection. For example, the chloramine loading of public swimming baths can be significantly reduced or high purity water can be produced for processes in the semiconductor industry and the optical industry.

TOC (Total Organic Carbon) reduction

COD (Chemical Oxygen Demand): destruction of organic contamination in water

Direct water photolysis (such as NDMA)

Disadvantages of Ultraviolet Water Treatment System

Disadvantages of Ultraviolet Water Treatment System

- Not removes dissolved impurities: UV water purifier kill bacteria and viruses but does not remove dissolved impurities such as pesticides, rust, arsenic, fluoride etc. Does not convert hard water to sweet, soft water.

- No water storage tank: Most of the UV water purifiers don’t have water storage tank. The user has filled water in the external bottle.

- Requires electricity: UV water purifier requires electricity to run. If in your area has frequent electricity cut off and water purifier don’t have storage tank then you don’t have any source for purified water until electricity came.

- Not effective on muddy water :UV water purifier is not effective when water contains muddy. In case muddy water, first water passes through any other purifier system then pass through the UV water purifier.

- UV light shutoff: As UV light is invisible, it’s very hard to know whether UV purifier is working or not. If UV purifier stops working and user unable to find out, results UV water purifier delivers impure water. That’s why most of the experts suggest replacing UV water purifier tube should have to replace once a year.

- UV rays does not remain in water once water is purified. In the case of UV rays miss any microorganism while purifying, that remaining microorganisms increase their population and impure the water. It is advisable to use chlorination after water purified through the UV.

Where can UV be used?

Short answer: everywhere! Ultraviolet (UV) disinfection of drinking water has been growing steadily in popularity, as people search for a chemical-free solution for ensuring their water is safe from microbiological contaminants.

- Homes and cottages: Home systems are point of entry (POE), which means they’re plumbed directly into the water line where it enters your house. This ensures clean, safe water is available at every tap in your home.

- Camps, RVs, and boats: If your water source is a lake, a well or an on-board supply, don’t let poor water quality ruin your recreation time. UV is a chemical-free solution to protect all outdoor enthusiasts.

- Schools, daycares, eldercare and healthcare facilities: The young, the elderly, and those with compromised immune systems are among those most susceptible to infection. In many jurisdictions, especially if the facility is served by a private water supply, water quality is subject to regulation.

- Offices and public buildings: It’s simply good business to ensure the quality and safety of the water provided for employees and visitors, from washrooms and drinking fountains, to water features.

- Restaurants, hotels and resorts: It’s hard to name an industry that relies more heavily on recommendations and word-of-mouth. Guest experience is everything. Water quality enhances food and beverages, and water safety ensures your reputation.

- Rainwater: More and more homeowners and organizations are opting to harvest rainwater as a private water source and disinfection of that water is required for potable uses

Will it Work for My Water?

The well water usually contains high risks of pathogens. Austro water tech helps you understand the UV water treatment effectively. Austro also helps you to find the levels of dissolved sediments, minerals like iron, manganese and sulfur. The factors which define the efficiency of an UV system. Though UV water purification systems are used as the last part of water treatment process, choosing an effective UV water system is important.

Are there any Health Risks from using Ultraviolet Water Treatment System?

There are three potential health risks associated with using UV devices – formation of disinfection byproducts; mercury exposure due to UV lamp

breakage; and direct exposure to UV light generated by the UV device. All these potential health risks are generally considered minimal. While there is evidence that UV can produce disinfection byproducts, UV produces far fewer disinfection byproducts compared to other chemical disinfectants typically used in drinking water treatment (e.g., chlorine, ozone, chlorine dioxide), Disinfection byproducts may cause adverse health effects if consumed in sufficient quantities for long periods of time. Most UV lamps used in drinking water treatment contain between 5 milligrams (mg) and 400 mg of mercury. There is a concern if a UV lamp breaks during operation the mercury could enter the treated water and be ingested.

Most UV devices have safety mechanisms installed to alarm or stop treatment or water flow if a UV lamp breaks or loses power for any reason. Additionally, if the quartz sleeve is not damaged or broken it may prevent mercury from entering the water if the lamp breaks. While this is a concern, the potential health risk from ingesting mercury is low. The health risks from direct exposure to UV from sunlight are well documented. There is a concern that a user could be exposed to UV light when using or maintaining a UV device. However, this poses a slight risk as UV devices are designed to operate in enclosed vessels and include safety mechanisms to prevent UV light exposure during maintenance.

No Comments

Sorry, the comment form is closed at this time.